Technology

At Savera, we are proud of our legacy of innovation, which has not only enhanced our internal processes, establishing us as a leader in quality and efficiency, but has also made a significant impact on the industry globally.

Some of our most significant milestones include:

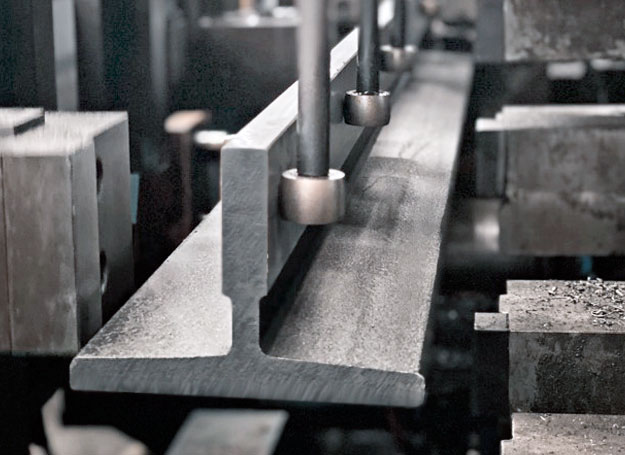

Development of automatic straightening lines that optimize workflow and enhance the precision of our products.

5 meter straightening: A proprietary design that has set a new industry standard for high quality guide rails.

Implementation of automated inspection machines to guarantee 100% process control.

We have invented the high-capacity super planer, a breakthrough that revolutionized guide rail manufacturing by improving both quality and efficiency.

We have developed modular solutions for ends machining, allowing for greater flexibility and adaptability in production.

Mechanical components technology

Our mechanical components division operates manufacturing centers with the most advanced technology for sheet metal processing: punching, laser cutting, bending, welding and painting. Fully automated areas to guarantee the safety of our staff, product quality and delivery times.

The processes are fully digitalized and interconnected via information systems designed and developed by our team of analysts and programmers.